Heat Sealing Plastic Sheeting

Once soft mold them into any shape you desire.

Heat sealing plastic sheeting. Work on a smooth glass surface as the heated plastic won t stick to glass. Primarily it protects walls floors and furniture from paint or other liquids. Rapid angular oscillations are applied to heat the plastic parts to be joined. The equipment must be programmed to stop when the parts are properly positioned for joining.

3 high frequency welding. Use heat from an iron to seal plastic bags. Plastic the hdx 20 ft. I show how to use a soldering iron to fuse plastic together.

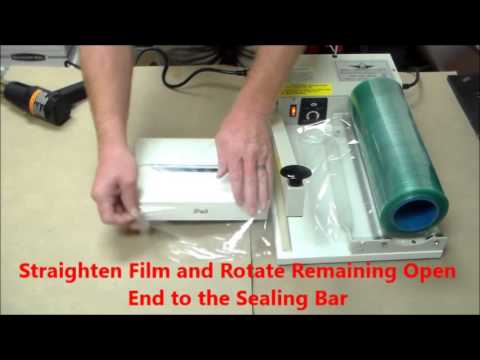

Vertical form fill seal vffs vertical baggers l bar i bar sealing horizontal form fill seal hffs flexible laminations stand up pouches usps automatable polywrap iqf frozen foods or heat shrink film. Maybe you don t trust the seal on a resealable bag or want to store something in a plastic bag that lacks a resealable strip. Also known as an impulse sealer a heat sealer uses a resistive heating element to seal and or cut thin plastic bags or sheets. 10 coupon applied at checkout save 10 with coupon.

Polyethylene plastic sheeting has a variety of uses in home maintenance. This plastic can be used to cover crawl spaces and as a temporary cover for equipment and supplies. Upon cooling they will be strong and permanent. This can be used to seal bags make them to the specific size of the object inside and create an.

Achieving an integral heat seal is the goal for. Rather than using continous heat which would turn the bag into a gooey edged mess it uses a timed impulse of heat hence impulse sealer. The hdx 20 ft. Just heat the sheets above 150 degrees f for 2 3 minutes until they turn from translucent to clear using a heat gun.

It can also be used to seal doors and windows to prevent harmful gases or materials from entering a room. Plastic sheeting is a general purpose plastic film for use in a variety of construction and diy projects.